Organizations need to buy components to make a finished good. All those components get wrapped up into a group called “Supply”. The components could be raw materials, co-packer pricing, product packaging or shipping cost. A great supply chain has a list/recipe of what components go into what finished goods -- Often called “Bill of Materials.”

When your forecast is capture at a very high level you miss out on details and have to guesstimate on details. One example is dollars. If I know the cases but have different pricing between customers I’ll have to guess at what the revenue should be.

One of the challenges to Bill of Materials is making sure all the items and quantities are all up to date. In some instances one component can go into multiple items. In other instances one component is only used in one item. A classic example is international languages. Just for one product you have to many different translations. Making one small change can expand into a day long task of manually updating 100’s of BOM. on the other hand not having one component can grid production to a halt.

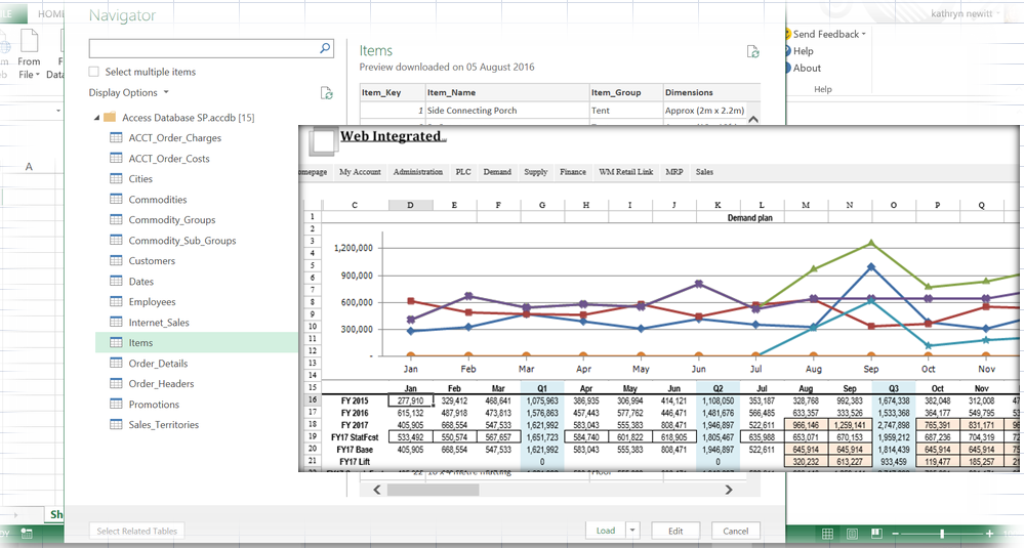

When the Bill of Materials is maintained in Web-Integrated tools updates are quick and easy. We can take in updates from a spreadsheet or manually change Bill of Materials with mass changes in the web pages.

With all the information up to date, all purchasing activities can be synchronized. All components can be available for scheduled production. All the inventory can be tagged with weeks of coverage. By far the best benefit of Web-Integrated is lowered finished goods AND lowered component inventory.